25.09.2018 Climatic - Corporate << Back

Breakthrough in advanced oxidation – removal of formaldehyde

As ambient air pollution is receiving increased attention and the mortality rate ascribed to it is reaching epidemic levels, solutions that can help abate air quality problems in industries are becoming increasingly sought after. The current market is abounding with products offering a variety of claims, most or all based on absorption filtration technologies (activated carbon/HEPA etc.) meaning that they function well when new, but rapidly lose efficiency as filters are saturated, requiring frequent replacement to remain effective.

To provide the industry with an efficient solution which overcomes the challenges presented by the present technology, in 2012, Infuser commenced development work on a sequential gas-phase-treatment method which applies a two-step oxidation process combining UV energy and catalysis. Finding the appropriate balance between UV energy and catalysis for removal of different pollutants has been the core of Infuser’s R&D effort. Work on this complicated task has shown that the two effects are not only additive but multiplicative when combined. In 2017, Infuser patented the solution where low wavelength ultraviolet gas phase oxidation followed by specific catalytic processes provides the basis for a technology that can pave the way for a sustainable air cleaning method.

Infuser’s technology has been applied at different industries and new applications are continuously being researched and tested. Our recent focus is on the removal of formaldehyde.

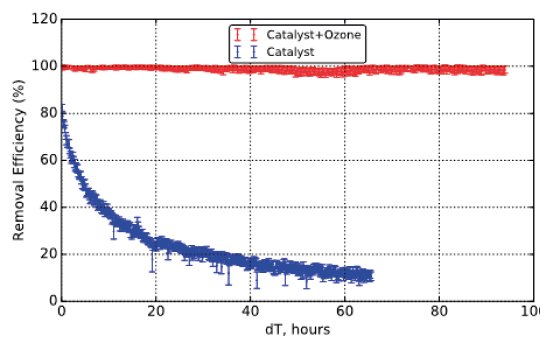

Infuser’s own tests have shown that when it comes to removal of formaldehyde, the standard adsorption catalysts reach a 50% removal efficiency in approximately 5 hours run time, at which point the catalyst performance has degraded to a level requiring replacement. The formaldehyde removal efficiency of a conventional adsorption catalyst is shown with the blue line in Figure 1. The standard catalyst exhibits typical adsorption characteristics with a steady, exponential decline over time and decreasing adsorption efficiency of formaldehyde. In the presence of ozone in optimal ratios, the Infuser Catalyst, however, maintains over 97% removal efficiency beyond 90 hours of run time with no clear reduction in efficiency, representing a truly catalytic process, shown with the red line in Figure 1.

Infuser has through the above tests proven that not only the concept works, but also that it removes formaldehyde efficiently. The oxidation chemistry that takes place on the catalyst surface, after initiation by radiation of the gas, has proven to extend the lifetime of filters and has formed the basis for the selection, design and application of this technology to formaldehyde related services.

Infuser (under the ™ CLIMATIC) is now looking for a partner in the industry to apply the technology in an industrial setting. Should you be interested in partnering up with us to run commercial tests for and at your facilities, we look forward to hearing from you.

Please feel free to download our PDF on the topic

Ayten Y. Wagner | e-mail : | Mobile: